LIFE SCIENCE AND PHARMACEUTICAL PROCESSES Hygienic safety valves for liquid chromatography systems

Liquid chromatography is a process that not only separates substances, but also identifies and quantifies them via standards (determines the exact concentration).

In biopharmaceutical production, this achieves optimal separation and purification of monoclonal antibodies, vaccines, plasma and therapeutic proteins.

Example: Liquid chromatography can be used to determine the concentration of a chemical substance (e.g. vitamin E in a vegetable oil).

Customised (valve) equipment for life science and pharmaceutical processes.

Challenges in choosing the right safety valve and extensive certifications also go hand in hand here and ensure that smooth operation, even under demanding cleaning and environmental conditions, is guaranteed at all times.

PERFECT PRODUCT SOLUTIONSThe challenge for GOETZE in choosing the right safety valve

- High response pressure of up to 21 bar

- Different blow-off capacities due to small and large CT systems

- Hygienic design

- Hygienic, electropolished surface on the inlet side according to customer specifications

- Special ASME compliant connections according to customer requirements

- Special certifications according to customer requirements (ATEX, ASME)

The situation at the chromatograph

The process liquid is heated up to 75 °C in different circuits before it is passed through the chromatography columns. These circuits must be protected against overpressure. The protection is primarily for thermal expansion, as well as protection against overpressure due to pump or valve failures.

Discover valve technology for hygienic applications

FLEXIBLE PRODUCT PORTFOLIOThe customised product solution

According to customer specifications, the GOETZE product portfolio provides several possible suitable valve series for life science and pharmaceutical processes of this type.

The decision was made in favour of the 420 and 451 series in a particularly hygienic design and with electropolished surfaces in contact with the process, especially in the inlet area. In addition, in this application, the valve position is transmitted to the control system at all times via proximity sensors.

Another important point for the customer was the fact that both valve series are available in different sizes, which means that the same series can be used for both small and large chromatography systems.

CUSTOMISED ADVICEFrom the engineering process to the certificates

Our valve experts were able to significantly support the customer's engineering process with the necessary calculations of the safety valves.

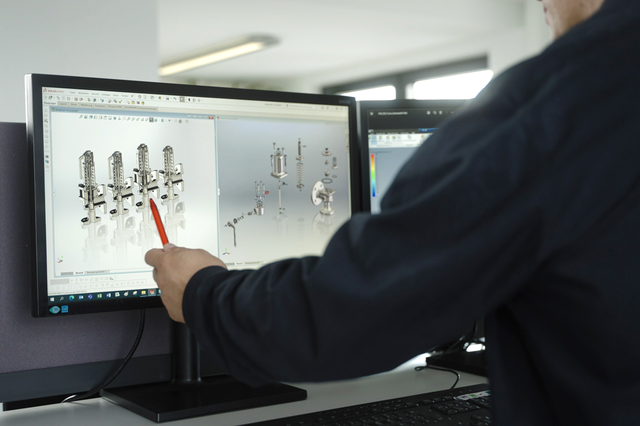

In the next step, the corresponding customer-specific 3D CAD models were created and integrated into the CAD models of the small and large plant for further planning.

Finally, the flexibility with regard to the required ASME-compliant connections and the short delivery time were also decisive criteria why the customer decided in favour of GOETZE valves.